Sawmill

We believe economics and efficiency must be planned from the beginning, therefore by processing the log into a board that suits the final needs of furniture is the main key. So that the recovery of wood output and material quality can be maximized.

Kiln dry

Reducing moisture content in wood is the main objective of this process. The correct KD schedule make the characteristics of the wood do not change like its nature. Each type of wood has different characteristics. Therefore, KD schedule is an art in the timber industry.

Moulding

To see the right component quality, the smooth 4 side process is the main objective of each component passing through this machine.

Laminating

Efficiency and design cannot be separated from the laminating process. The width of a particular component requires passing this process.

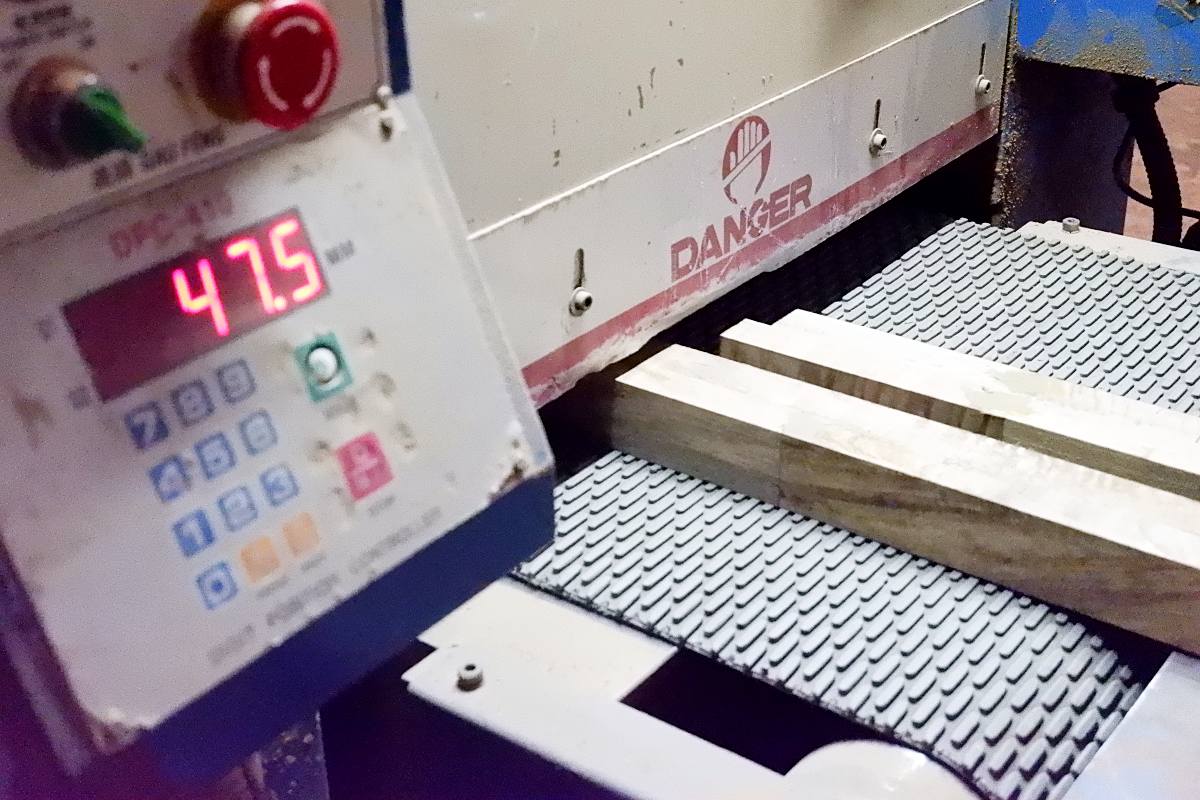

Sanding Machine

Sanding is the first process of component smoothing, so that in the next refining stage, the components that meet the fineness standard are obtained before entering the coating process.

Construction

The process of forming components according to location, function and position. sometimes repetition is carried out at certain points which ultimately produce aesthetics in furniture.

Asembling

each component is rafted and ascertained in the right position, in terms of aesthetics, neatness, cleanliness is very much considered at this stage.

Finishing

Many types of coating material are applied to produce the final texture desired or according to order and design

Packaging

Handling defects are a consideration of which protection protection is needed. each stage must be ensured to pass the drop test.